You don't have any items in your quote list.

Can you connect two pressure washer hoses together?

August 10, 2023

Pressure washing becomes a hefty task if the equipment is not in accordance with the requirements of the worker. The length of the hose pipe alters the maneuverability of the equipment, the pressure rating and the efficacy of the wash. Hence, length is a crucial factor to consider while performing a pressure washing job. This takes us to our question- Can we connect two pressure washer hoses together and make the overall hose length longer? Or how to extend a pressure washer hose length? In this blog we will be discussing the same and will also explore different ways to do the same, the pros and cons of it and the process of disconnection of two hoses as well.

The initial question that arises in one’s mind is whether or not we can connect two pressure washer hoses. The answer is yes! We can connect two hoses together in order to form a longer hose. However, it is very important to take into account the diameter of the hoses and the pressure rating of the fitting to prevent any kind of wear and tear of the pressure washer.

Let us discuss the process of connecting the hoses. One can follow these simple steps to ensure convenient connection:

Step 1: Turning off the pressure washer and disconnecting it from the power source

Ensure your safety before performing the task by disconnecting your power washer from its energy source. Once the pressure washer is disconnected, we move to the next step.Step 2: Checking the ends of both the hoses to identify the connectors

Check both hose ends to see the types of connectors required to connect both of them. Ensure to check the ID of the hoses to select ideal fittings for them.Now this is a very important step to ensure a leak free connection and smoothen the process of pressure washing. Let us dive deep into the selection of the connector.

Connector fittings are majorly categorized on the basis of type and size. To ensure that you get the right size, check the ID of your hose and buy the connection of the same ID. The next consideration is the type. Connectors majorly come in two types: The quick connects and the threaded fittings.

Threaded fittings are one of the most conventional kinds of fittings in the market. Majorly used for small pipe fittings, threaded fittings are low-cost and are used in non-critical applications such as domestic, fire safety systems etc. These need to be connected manually using some connecting agent like a sealant.

Quick connects, as the name suggests, are the couplings used to connect a tubing and a tool very quickly and efficiently. Also known as quick connect couplings and quick disconnects, these have made the process of connection and disconnection hassle free.

Once you have chosen the fitting, we move to the next step.

Let's talk about specific types of connections for pressure washers. To buy an ideal connector for your hose, you must check the user manual of the pressure washer because every machine works on a different configuration.

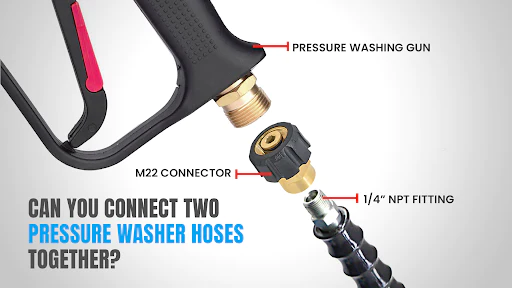

Pressure washer fittings are either M type or J type. Let us discuss both of these respectively:

- M22 fittings: M22 stands for a 2 inch male end thread. Made of two pieces of metal together. They are commonly used with pumps, hoses and spray guns.

- J type fittings: J type fittings are peculiar to pressure washers and are used to connect hose to the pump. They use either a screw-on mechanism or a clamp.

Step 3: Making and tightening the connection

Once you have bought the connectors, all you need to do is to connect each end of the hose to the connector and tighten the connection to ensure a leak free fluid flow.Step 4: Checking the connection

Test the connection for any leaks by turning on the pressure washer and checking for water dripping or spraying from the connection. This step will avoid any kind of pressure washer hose leaking.This process doesn’t take more than 15 minutes and makes the length of the hose longer. This process answers our initial question of how to extend pressure washer hose.

However there are some pros and cons associated with the connection of pressure washers hoses together:

PROS:

- Increases the length of the hose

- Allows you to clean a larger area without having to move the pressure washer.

- Can provide more flexibility when cleaning hard-to-reach areas.

Saves time

CONS:

- Can decrease the pressure and water flow rate, leading to less effective cleaning.

- Increases the risk of pressure washing hose leaking and damage to the hoses and equipment if not done properly.

- A longer hose can be tough to move and handle.

Now once the connection is established and the longer hose is operating smoothly, one may feel a need of having the original length of the hose back. Let us discuss the process of removing the connectors to get the original length. The process of disconnection is very similar to that of connection.

First up, turn off the pressure washer and disconnect it from the power source to ensure your safety. Now, locate the hose connector on the pressure washer.

Press the locking mechanism on the connector and pull the hose out of the connector. If the connector is stuck, use pliers or a wrench to loosen it before pulling the hose out. The hose will be disconnected from the hose attached to the pressure washer and the pressure washer hose will regain its original length.

Another question that comes to mind while choosing an extension hose is if all the pressure washer hoses are the same. The answer is no. All the pressure washer hoses are different in terms of diameter, length and pressure rating. One must choose a hose depending on the diameter of the hose attached to the pressure washer and the pressure rating required to carry out the washing job.

A common problem that a pressure washing professional faces is the wear and tear of the hose attached to the pressure washer. In case the hose is damaged due to abrasion, excessive usage or any external factor, the hose needs to be replaced. In order to replace the existing hose, remove the hose from the pressure washer and measure its length and ID. Buy a hose of similar ID in the required length and connect one end of the hose to the pressure washer and the other end to the spray gun/wand. Ensure that the connections are tight and secure. Check the connections by operating the equipment and voila, there you have a brand new pressure washing assembly.

After analyzing all the key factors involved in hose connections, we can conclude that we can connect two pressure washer hoses together. We just need to consider factors such as the hose fittings, desired length and pressure rating beforehand. This comes with its own pros and cons and hence depends entirely on the requirement of the pressure washing professional.